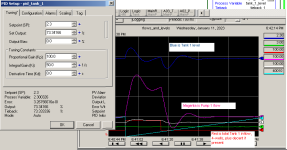

It takes around 40minutes, from ~08:00 when the decant cycle starts and the level was somewhat steady, for the flow at ~100gpm (4-wells base load, no decant) to increase to 115gpm (decant load) at ~08:35, at which point net flow is 0 and the level is not changing.

Over that time, the level initially increases by 1.7ft-, from 2.3ft+ to 4.0ft.

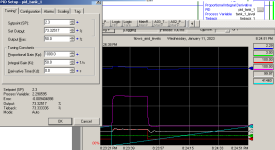

By the end of the decant flow (115gpm), because the level has not recovered and has instead almost completed its first oscillation, it is ~1.98 and increasing.

Although the relative conditions are not identical to when the decant flow started, when the decant flow stops I would expect a similar initial swing with the level decreasing by 1.7ft (or so, maybe more, maybe less, but in that neighborhood), which would almost certainly pull the level below the 1ft low limit.

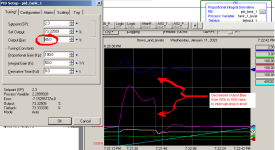

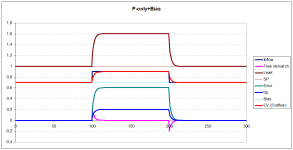

Increasing Kp will increase the flow more quickly as the level rises, which will attenuate the level rise, which in turn will attenuate the Integral Accumulation, which in turn will mean the level will not need to go as low to eliminate the excess Integral Accumulation.

P.S. Yes, I am groaning with you, @Peter, that I explain it this way, but I don't think throwing the Laplace domain, which is of course the right thing to do, at OP is going to help here.

Maybe we could set up a Jupyterlab page to simulate this, with time-domain and s-/Laplace-domain (complex-plane, IIRC?) plots. Once validated (although the model is so simple, that should be trivial), OP could tweak the gains to see that there is no way to improve on the optimal poles.