I'm starting learning ladder programming.

I bought the FX3U kit + coolmay HMI from aliexpress.

I'm doing basic testing and uploading codes.

I found this example on YouTube about RAMP function. According to the layout:

The code in this video:

https://www.youtube.com/watch?v=9-vyN9eSGFk

I'm not sure what is RAMP, is it sending analog voltage on DA0 or DA1 ?

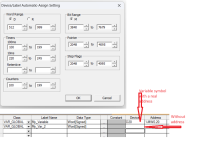

So I did the example on gx works2 and compiled the code and did the debugging simulation and it worked, but when I wanted to upload the code to the PLC I got this message:

What is the problem ?

Another request, is there any series of tutorials or a document about FX3U instructions ?

I bought the FX3U kit + coolmay HMI from aliexpress.

I'm doing basic testing and uploading codes.

I found this example on YouTube about RAMP function. According to the layout:

The code in this video:

https://www.youtube.com/watch?v=9-vyN9eSGFk

I'm not sure what is RAMP, is it sending analog voltage on DA0 or DA1 ?

So I did the example on gx works2 and compiled the code and did the debugging simulation and it worked, but when I wanted to upload the code to the PLC I got this message:

What is the problem ?

Another request, is there any series of tutorials or a document about FX3U instructions ?