ThomasHunter

Member

I am a complete newbie to this stuff and wanted to try this out and was looking for any information on how I can complete this by Wednesday evening. Currently taking a college evening course and I am struggling with the PLC portions.

If you are thinking - 'Do you want us to do your assignment for you?'

No. I will be tested in a couple of weeks and have to be left with my skills and knowledge on this subject by creating a program that will not be known to me until test day.

_____________________________________________________________

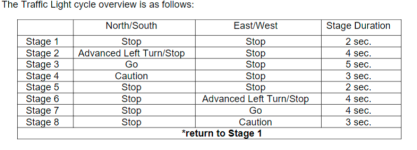

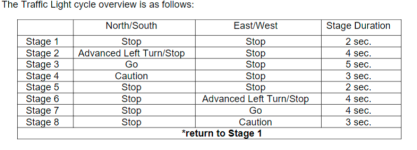

Assume that the lights are field-wired in parallel so that there is only one PLC address required per stage (i.e. North/South Green, East/West Yellow, Advanced Left Turns, etc.).

Your program must operate the Traffic Light system in an acceptable and safe manner.

Therefore the following must be taken into consideration:

a) The Red Light Stages must overlap by 2 seconds to prevent accidents

b) If the Master Control is manually disengaged at any point during normal operation the Red lights must flash until Master Control is engaged (at which point the lights will operate normally with North/South traffic flowing first)

Overview: https://imgur.com/a/TDJElmO

_____________________________________________________________

Any information is greatly appreciated. The reason for my struggle is that we get no practice sessions and need to plan and build the programs in less than a couple of hours.

Thank you for your time.

If you are thinking - 'Do you want us to do your assignment for you?'

No. I will be tested in a couple of weeks and have to be left with my skills and knowledge on this subject by creating a program that will not be known to me until test day.

_____________________________________________________________

Assume that the lights are field-wired in parallel so that there is only one PLC address required per stage (i.e. North/South Green, East/West Yellow, Advanced Left Turns, etc.).

Your program must operate the Traffic Light system in an acceptable and safe manner.

Therefore the following must be taken into consideration:

a) The Red Light Stages must overlap by 2 seconds to prevent accidents

b) If the Master Control is manually disengaged at any point during normal operation the Red lights must flash until Master Control is engaged (at which point the lights will operate normally with North/South traffic flowing first)

Overview: https://imgur.com/a/TDJElmO

_____________________________________________________________

Any information is greatly appreciated. The reason for my struggle is that we get no practice sessions and need to plan and build the programs in less than a couple of hours.

Thank you for your time.