Mas01

Member

As per the title. This might seem like a basic question to many, but I'm unclear about the difference between a coil ( ) and an application instruction [ ]?

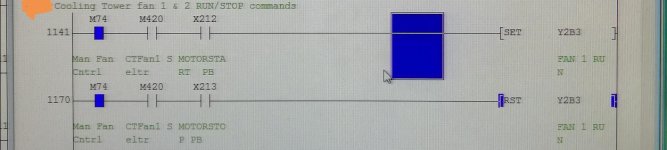

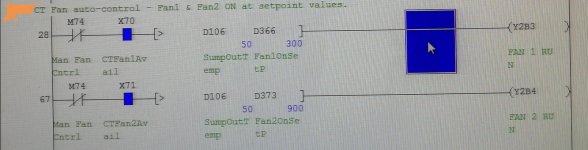

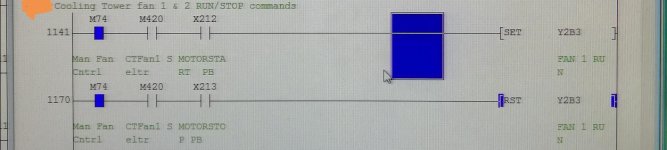

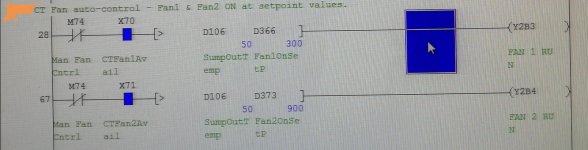

See the example below. I want to switch on a fan via output Y2B3.

When I operate the rig and set M74=true , M420=true and I press the pushbutton X212, on line 1141 , Y2B3 momentarily gets SET. Does line 28 do a reset and "cancel out" the switching on of the fan?

See the example below. I want to switch on a fan via output Y2B3.

When I operate the rig and set M74=true , M420=true and I press the pushbutton X212, on line 1141 , Y2B3 momentarily gets SET. Does line 28 do a reset and "cancel out" the switching on of the fan?