Question to anyone with ideas about my thoughts on upgrading a very vintage timer, which is being used to switch between 2 5hp domestic water booster pumps for maintaining system pressure in 10 story building. Every 24 hours the pumps switch between duty. There is no lead or lag built into the system and as far as I can tell the Mercroid high pressure limit switches have never been tripped (pressure being made) They just run 24/7 year in and year out.

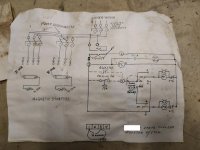

I've attached the schematic, a picture of the components and a picture of the timer and alternating relay. I also attached a pic of the type of timer/relay that I believe could replace this older system. I like the idea of mounting the digital timer through the front panel door. Any thoughts on wiring, potential issues, confirmation or best recommendations for this simple task...simple I'm guessing from the view point of the average contributer to this site anyway.

thanks,

I've attached the schematic, a picture of the components and a picture of the timer and alternating relay. I also attached a pic of the type of timer/relay that I believe could replace this older system. I like the idea of mounting the digital timer through the front panel door. Any thoughts on wiring, potential issues, confirmation or best recommendations for this simple task...simple I'm guessing from the view point of the average contributer to this site anyway.

thanks,