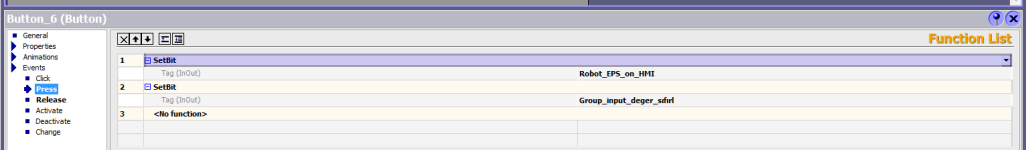

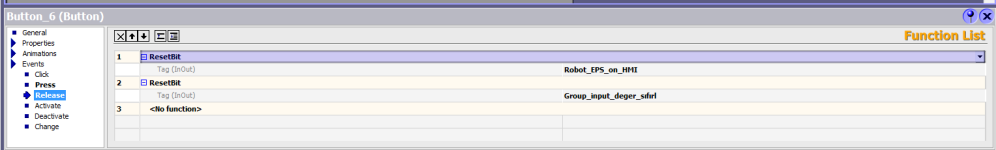

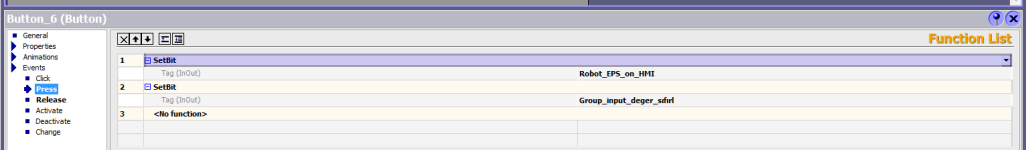

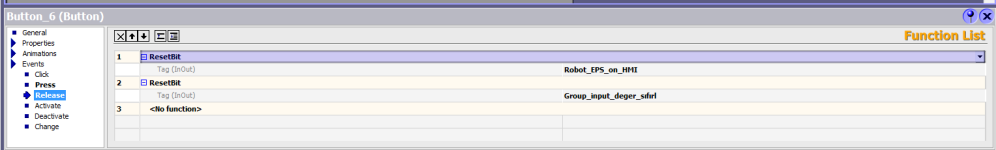

Hello to everyone. I change the value of a "PQW" with a button in Wincc flexible. The code of the button is defined as M102.0. Value reset address is defined as M101.2. What I want is that when I press the button, the value (8) I set is transferred to "PQW", and when I take my hand off the button, the "PQW" value is "0". I tried a lot, but the value sometimes changes in a ridiculous way, but most of the time it doesn't, I couldn't make sense of it. I guess something is wrong or missing on the HMI or the code but I don't quite understand. Can you please help? Or can you suggest alternative solutions? The 1st image is the code I wrote, the 2nd image is the button Press feature, the 3rd image is the button release feature.

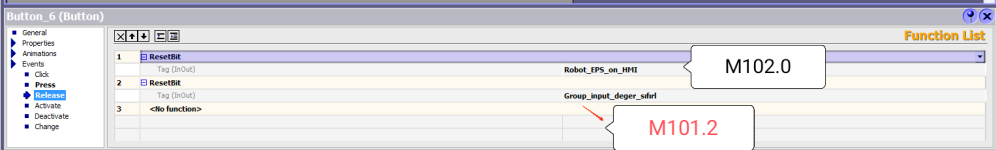

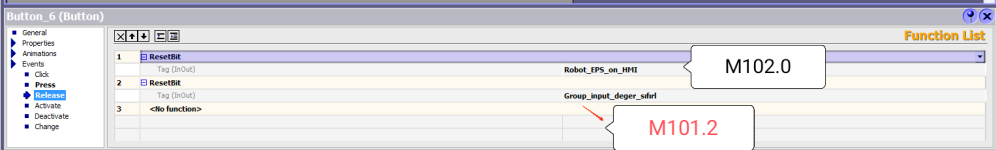

I've added the 4th picture to be more descriptive

I've added the 4th picture to be more descriptive

Last edited: