Hi. First post here. Hoping to get some help with a m221 im using with machine expert basic to communicate with an omron HMI.

Im using Ioscanner with a TCP gateway to communicate to the HMI via Modbus TCP. I'm able to write values to the HMI without issue. The problem is that I encounter "thrashing" where my inputs are opening and closing like mad.

I was tinkering with poll rates in the channel settings in machine expert and am able to eliminate the thrashing by having read at say 250ms while write channel updates every 800ms.

I find this is not an ideal solution. The PLC will sometimes miss the input to true when write channel updates are scheduled over 500ms. I'm looking for a way to reliably write and read my digital variables to the HMI and back. Screen shots attached.

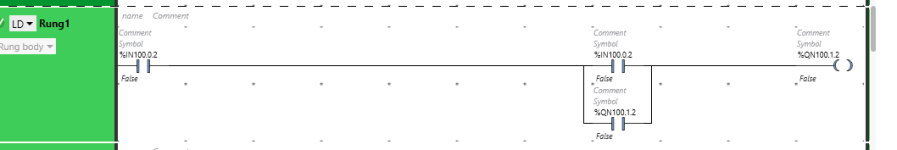

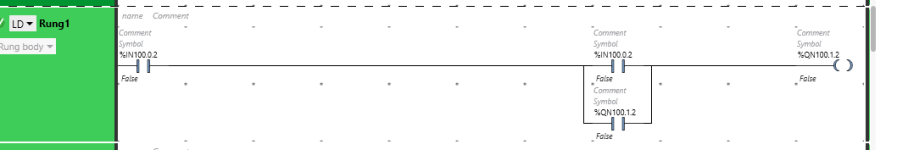

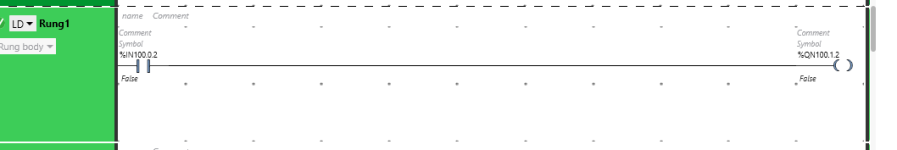

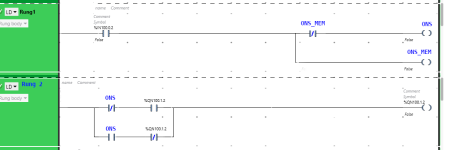

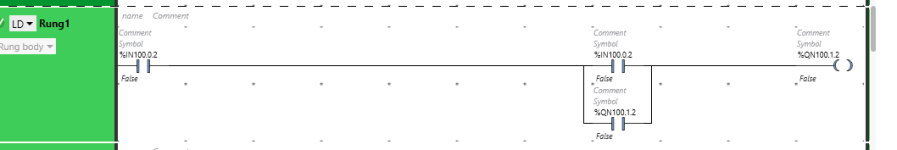

With the logic pictured, the button status will cycle between true and false indefinitely forever when I trigger the input true on the HMI. I am using a button on the HMI that will alternate states for the single button logic.

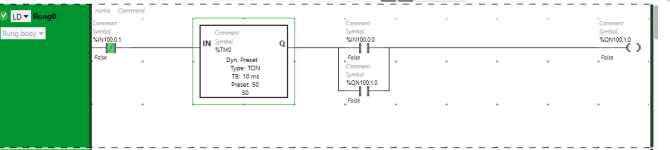

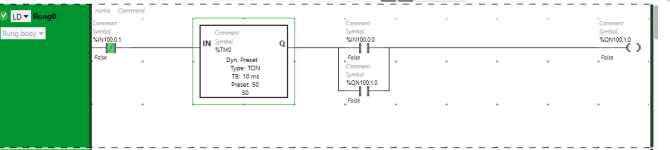

The dual button logic uses one button on and another button to turn off. It seems to be more reliable but still misses input sometimes and will not trigger the bit occasionally.

Im using Ioscanner with a TCP gateway to communicate to the HMI via Modbus TCP. I'm able to write values to the HMI without issue. The problem is that I encounter "thrashing" where my inputs are opening and closing like mad.

I was tinkering with poll rates in the channel settings in machine expert and am able to eliminate the thrashing by having read at say 250ms while write channel updates every 800ms.

I find this is not an ideal solution. The PLC will sometimes miss the input to true when write channel updates are scheduled over 500ms. I'm looking for a way to reliably write and read my digital variables to the HMI and back. Screen shots attached.

With the logic pictured, the button status will cycle between true and false indefinitely forever when I trigger the input true on the HMI. I am using a button on the HMI that will alternate states for the single button logic.

The dual button logic uses one button on and another button to turn off. It seems to be more reliable but still misses input sometimes and will not trigger the bit occasionally.