drbitboy

Lifetime Supporting Member

Isn't the normal thing to have one VFD/motor set the speed, and run the other VFD/motor at some fraction above or below that by some percentage but torque limited, so the torque limit will always be active and set the tension?

E.g. run the unwind VFD on speed control at speed SUW = linespeed/(UnwindDiameter*PI) RPM, and run the wind at speed SW = linespeed*105%/(WindDiameter*PI) with a torque limit of (TargetTension*WindDiameter/2), so the wind roll will always be applying a linear tension of TargetTension. It would be preferable to measure UnwindDiameter and WindDiameter, but modelling them would be another option.

Knowns

For any time t at and after that:

The θ and D calculations, in Models 4 and 2 above, are based on the geometric area model in the first image below.

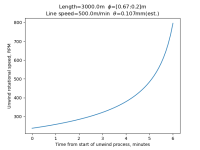

A sample plot of unwind RPM vs. t is in the second image below.

Caveats

E.g. run the unwind VFD on speed control at speed SUW = linespeed/(UnwindDiameter*PI) RPM, and run the wind at speed SW = linespeed*105%/(WindDiameter*PI) with a torque limit of (TargetTension*WindDiameter/2), so the wind roll will always be applying a linear tension of TargetTension. It would be preferable to measure UnwindDiameter and WindDiameter, but modelling them would be another option.

Knowns

- Ldot, m/minute, target line speed

- De, m, unwind diameter when empty

- Df, m, unwind diameter when full

- Lf, m, linear length of material from full (Df) to empty (De)

- RPM, revolution/minute, unwind rotation rate

- θ, m, thickness of one layer on unwind

- π, 3.14159...m/m, ratio of circumference of roll to its diameter

- t, minutes, time of unwind

- t = 0 at beginning, when unwind diameter is Df

- t = Lf/Ldot at end, when unwind diamter is De

- D, m, instantaneous diameter of unwind roll

- L, m, instaneous linear length of material

- L = Lf, at time t=0, when unwind diameter is Df

- L = 0, at time t=Lf/Ldot, when unwind diameter is De

- RPM = Ldot/D, revolutions/minute - calculate instantaneous RPM as a function of D, i.e. to yield linear speed of Ldot when unwind diameter is D

- D = SQRT(De**2 + (4 θ L / π)), m - calculate diameter of roll as a function of L i.e. of length of material left on roll

- L = Lf - Ldot t, m - calculate length of material remaining to unwind, as a function of time t

- θ = π (Df**2 - De**2) / (4 Lf), m - calculate average thickness of one layer, from known initial parameters

For any time t at and after that:

- calculate L from t in Model 3,

- calculate D from L and θ in Model 2,

- calculate RPM from Model 1.

The θ and D calculations, in Models 4 and 2 above, are based on the geometric area model in the first image below.

A sample plot of unwind RPM vs. t is in the second image below.

Caveats

- I am not saying this model will work; this is just a model with the parameters the OP said they already have, plus an assumed known value for Lf.

- Even the small [one part in 1e7] roundoff errors inherent in 32-bit floating point values from the calculation of θ could accumulate significant errors in D near the end of the unwind process

- Assumes mean per-layer thickness, θ, is constant, and any variation averages out

- Assumes total length to be unwound between Df and De is known, i.e. Lf

- Assumes unwind roll accelerates instantaneously at t=0 from 0 to RPM = Ldot/Df

Last edited: