ganutenator

Lifetime Supporting Member

I am finally lucky enough to work w/ an actual high level programmer.

I can follow a tag from the pnp junction up to an hmi.

He knows the other side.

He often jokes that together, we actually make a good programmer.

He is starting to dive into the home made hmi aspect and data collection.

I'm explaining everything I know about modbus tcp to him.

I have to hold laughter back when I state things like: It's an open protocol.

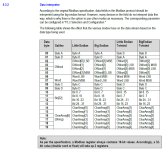

Then he asks why 4X:12,289 equates to %MW1 or 40001 or 40002 et al.

It's just a serial modbus msg wrapped in a packet in a pocket in a socket....

I can follow a tag from the pnp junction up to an hmi.

He knows the other side.

He often jokes that together, we actually make a good programmer.

He is starting to dive into the home made hmi aspect and data collection.

I'm explaining everything I know about modbus tcp to him.

I have to hold laughter back when I state things like: It's an open protocol.

Then he asks why 4X:12,289 equates to %MW1 or 40001 or 40002 et al.

It's just a serial modbus msg wrapped in a packet in a pocket in a socket....