Hi. I have taken over a Building Management System that hasn’t performed well since installed. It’s a ControlLogix main with wireless messaging to a Micro820 at each roof unit. Many units have a PF525 running the fan. The 820 has temperature sensors, enables or controls the fan, and enables any number of heating and cooling stages if applicable to the unit. I have the communication and preliminary control working well. Now I’m looking at how to best control multiple cooling or heating stages. As built had a five minute delay between stages, nothing smarter than that.

I haven’t really done anything with HVAC control outside of this project. I’m wondering how a ‘real BMS’ would handle stage control. I haven’t seen typical or example control algorithms in the videos and web pages I’ve found. I think that using fewer stages longer is generally more efficient than shorter cycles of more stages, so that is a goal unless someone has better information.

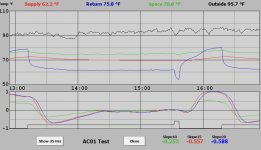

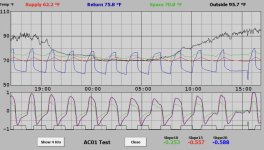

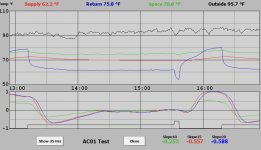

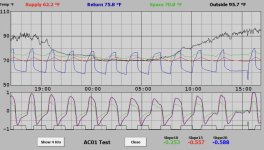

To start, I made a trend of one non-VFD AC unit. One cooling stage has been sufficient until the afternoon heat today. One stage was holding almost at the cutoff point, but didn’t quite have enough and I enabled a second stage. That quickly reached temperature and the compressors stopped until the next cooling cycle. In this example, setpoint is 71 with 1.5 hysteresis. The fan runs continuously.

The top chart shows various temperatures. From my research, supply and return probes are backwards. I’ll fix that. In the bottom chart, the black line shows active cooling stages. The rest of the bottom is three different ways I calculated the room temperature slope of 15 second samples. Above zero is getting warmer; below zero is getting colder. Slope10 is the average of the previous five minutes relative to the average of the five minutes before that. Slope20 is similar in 10 minute blocks. Slope15 is five minutes, skip five, and the five before that. Maybe I should calculate the slope of the slope. Any suggestions here?

The logic is my preliminary idea for stage control. Basically, I’ll enable another stage after a delay if temperature is moving from the setpoint and also outside of the hysteresis. Should I have a timeout and enable another stage at some point if it’s holding but not reaching the stop limit?

Some units with heat and/or cooling have a VFD. Anything particular come to mind regarding that? I’m sure I’ll want some minimum speed that maybe should increase with number of stages enabled.

So far, I only see cooling. Heat is a couple months away. Thank you everyone.

I haven’t really done anything with HVAC control outside of this project. I’m wondering how a ‘real BMS’ would handle stage control. I haven’t seen typical or example control algorithms in the videos and web pages I’ve found. I think that using fewer stages longer is generally more efficient than shorter cycles of more stages, so that is a goal unless someone has better information.

To start, I made a trend of one non-VFD AC unit. One cooling stage has been sufficient until the afternoon heat today. One stage was holding almost at the cutoff point, but didn’t quite have enough and I enabled a second stage. That quickly reached temperature and the compressors stopped until the next cooling cycle. In this example, setpoint is 71 with 1.5 hysteresis. The fan runs continuously.

The top chart shows various temperatures. From my research, supply and return probes are backwards. I’ll fix that. In the bottom chart, the black line shows active cooling stages. The rest of the bottom is three different ways I calculated the room temperature slope of 15 second samples. Above zero is getting warmer; below zero is getting colder. Slope10 is the average of the previous five minutes relative to the average of the five minutes before that. Slope20 is similar in 10 minute blocks. Slope15 is five minutes, skip five, and the five before that. Maybe I should calculate the slope of the slope. Any suggestions here?

The logic is my preliminary idea for stage control. Basically, I’ll enable another stage after a delay if temperature is moving from the setpoint and also outside of the hysteresis. Should I have a timeout and enable another stage at some point if it’s holding but not reaching the stop limit?

Some units with heat and/or cooling have a VFD. Anything particular come to mind regarding that? I’m sure I’ll want some minimum speed that maybe should increase with number of stages enabled.

So far, I only see cooling. Heat is a couple months away. Thank you everyone.