I know there have been several posts on this subject but...

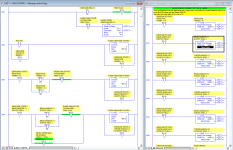

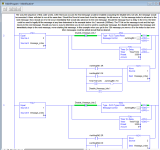

Is there a best practice for setting up multiple messages in a Micrologix 1400? I've seen it done several ways and most of the AB examples just show a single message.

My main question is timing and proper cascading. Do the MSG instructions just need to stay true for a scan for them to execute properly? Is there a downside if they are true for multiple scans? If you daisy cascade them with the DN bits what is the best way to reset the first MSG? Unlatching the EN bit?

Is there a best practice for setting up multiple messages in a Micrologix 1400? I've seen it done several ways and most of the AB examples just show a single message.

My main question is timing and proper cascading. Do the MSG instructions just need to stay true for a scan for them to execute properly? Is there a downside if they are true for multiple scans? If you daisy cascade them with the DN bits what is the best way to reset the first MSG? Unlatching the EN bit?