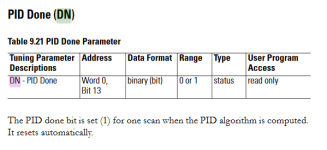

All this recent talk of PID brought me back to an issue I was looking at a few months ago.

My next project will involve cycling a valve to provide a PID controlled heating function.

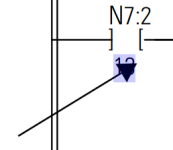

In the screenshot below, we see an example provided by Rockwell in the SLC instruction set manual of how to convert a PID CV output to a "time proportional" digital output.

But they managed to obscure an address with an arrowhead. See the red circle. Can someone take a guess as to what is under that arrowhead?

Thank you kindly!

My next project will involve cycling a valve to provide a PID controlled heating function.

In the screenshot below, we see an example provided by Rockwell in the SLC instruction set manual of how to convert a PID CV output to a "time proportional" digital output.

But they managed to obscure an address with an arrowhead. See the red circle. Can someone take a guess as to what is under that arrowhead?

Thank you kindly!