Jemeu

Member

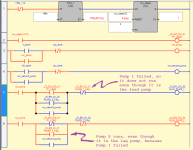

In this project I wanted two pumps to alternate between lead and lag. The controller is a Micro810.

I'm using a counter to dictate whether pump 1 or pump 2 is in lead.

If the lead pump happens to fail I wanted to force the lag pump to become the lead pump using the MOV instruction to move a number to ALT_COUNT.

ALT_COUNT was 1 so P2 = lead. I failed P2 in testing so rung 9 moved a 0 into ALT_COUNT making rung 9 true. My main concern was Rung 7 & 8 for some reason remained true

This is how I normally do it on RSLogix500, but it didn't for me here. But I programmed a workaround in the Micro810 so now that works.

There's a oneshot before the counter maybe the counter doesn't work like a counter in Logix500 and 5000. These are the only MOV instructions in the program and there is only one counter I can upload another picture later of how I have that working.

I'm using a counter to dictate whether pump 1 or pump 2 is in lead.

If the lead pump happens to fail I wanted to force the lag pump to become the lead pump using the MOV instruction to move a number to ALT_COUNT.

ALT_COUNT was 1 so P2 = lead. I failed P2 in testing so rung 9 moved a 0 into ALT_COUNT making rung 9 true. My main concern was Rung 7 & 8 for some reason remained true

This is how I normally do it on RSLogix500, but it didn't for me here. But I programmed a workaround in the Micro810 so now that works.

There's a oneshot before the counter maybe the counter doesn't work like a counter in Logix500 and 5000. These are the only MOV instructions in the program and there is only one counter I can upload another picture later of how I have that working.

Last edited: