I do not have an accumulating length measurement but I know the line speed. I do not have an encoder but I have a sensor in the winder pulley so I can calculate the line speed.

...

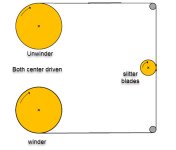

I am trying to control the linear speed of the unwinder. Currently to control the VFD 527 you can use motion commands.

Maybe I am naive, and we are overthinking this, and all OP is actually asking for is a feedback control loop using the pulley sensor data? The unwind motor speed is going to smoothly increase after the initial start, so even a simple floating control on the bottom half of a deadband might solve this. Or perhaps a speed ramp with a variable, slowly increasing slope (which is a model of the reciprocal of diameter, or similar)?

@ELGC/OP: I think we are almost there, if you could list all of the signals coming into the PLC, and all the controls going out, and the PLC model number, and answer the questions below, that should finish the data gathering step.

Most PLC programs are a model of a physical process, they don't model every atom and photon, but they model what they can from the available input measurements, physical laws and principles, approximations assumptions, etc. The primary design choice is the fidelity of the model to the physical process, and that is usually limited by the available inputs.

For example, in an earlier post you wrote that you were going to develop a table of diameter vs desired speed vs time. That is a model of the process, and you are probably going to do it in a spreadsheet. For my money it would be more flexible to code that model's equations into the PLC to execute in real time. So if a run comes up that is not in your table, or the process changes e.g. the motor acceleration capability on startup, then you don't have to go back to the spreadsheet.

0) What is the ultimate goal here? Is it to be able for the PLC to continually have, or calculate, a target speed that can be converted to a series of motion commands in real time?

0.1) What level of PLC skill do you possess, and what level of help are you asking for? E.g. some prototype PLC code you can tweak and insert into your program? Or the equations for a model that you will convert to PLC code?

1) What is the range of the values (diameter, line speed, etc.) you expect to see? What level of accuracy is needed for the unwind speed control (1%? 10%? 0.01%)?

2) How is the line speed calculation made from the sensor on the pulley? If the sensor is sending pulses to the PLC, one per some fixed length, then that could be also used to acculturate length for the diameter model. Even if not, the speed calculation result could be numerically integrated at regulator time intervals to model an accumulator.

3) I am a noob to motion controls, but I have seen other posts where VFD/motor combinations have been used for position control. Could someone point me to a link about this, or give a rough description of what is going on, or what these "motion commands" are and how they work, what issues them, over what medium/protocol, etc.?