[email protected]

Lifetime Supporting Member

I am trying to convince myself to come around to the new Unistream.

I just quoted a small panel expecting to use my default Automation Direct 10" C-More and the new DoMore but once I tallied up the cost for I/O (20 in, 30 out digitals and 20 analog in (Mostly type K thermocouples)..

I am attracted to the 16/16/2 cards from Unitronics and the new Unistream. A long time friend/vendor is pushing I try.

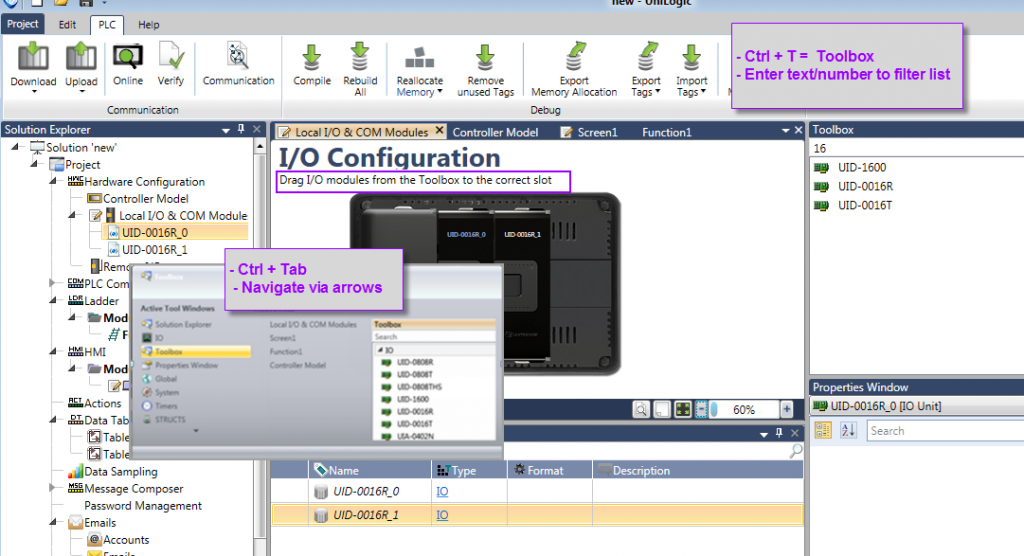

So I downloaded the FREE software and I immediately am taken back to why I have made NO attempt to try this platform in the past.

I'm a ladder guy. I have used Modicon and Siemens and I get the visual block method..... Don't like it ....

So who here loves the UniStream and can show me / explain the benefits.

If you are FLUENT and an expert in Unitronics and have actually taken a UniStream and linked to a remote I/o card and setup mixed type thermocouples and 4-20mA inputs in a project and are comfortable doing this again with ease....... I am happy to pay you to remote in webex and watch you do this setup.

If I see it once I'll have it.

I started knotting a crude noose out of dental floss watching the tutorials and gave up.. I need a speed lesson in this or I just won't use it.

I just quoted a small panel expecting to use my default Automation Direct 10" C-More and the new DoMore but once I tallied up the cost for I/O (20 in, 30 out digitals and 20 analog in (Mostly type K thermocouples)..

I am attracted to the 16/16/2 cards from Unitronics and the new Unistream. A long time friend/vendor is pushing I try.

So I downloaded the FREE software and I immediately am taken back to why I have made NO attempt to try this platform in the past.

I'm a ladder guy. I have used Modicon and Siemens and I get the visual block method..... Don't like it ....

So who here loves the UniStream and can show me / explain the benefits.

If you are FLUENT and an expert in Unitronics and have actually taken a UniStream and linked to a remote I/o card and setup mixed type thermocouples and 4-20mA inputs in a project and are comfortable doing this again with ease....... I am happy to pay you to remote in webex and watch you do this setup.

If I see it once I'll have it.

I started knotting a crude noose out of dental floss watching the tutorials and gave up.. I need a speed lesson in this or I just won't use it.

Last edited: