40mpg

Member

Hello all,

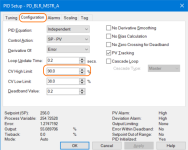

I have an issue with a PID block in RsLogix 5000.

The parameters are

P: 3.25

I: 0.11

D: 0.01

The Set Point is 71 psi

This loop has been used for over a decade. The problem is the PV never reaches the Set Point of 71, it hovers at 68-69 and cuts off. I've tried to increase the P, and it still hovers at 68-69. Lower I and D to 0 and it never goes pass 5 psi.

I am starting to think the valve ( the device the CV is trying to control) is starting to go bad after 16 years in operation.

The Output always maxes at 2 Volts ( 0 - 10 Volts).

Anyone have any suggestion on what I can do?

I have an issue with a PID block in RsLogix 5000.

The parameters are

P: 3.25

I: 0.11

D: 0.01

The Set Point is 71 psi

This loop has been used for over a decade. The problem is the PV never reaches the Set Point of 71, it hovers at 68-69 and cuts off. I've tried to increase the P, and it still hovers at 68-69. Lower I and D to 0 and it never goes pass 5 psi.

I am starting to think the valve ( the device the CV is trying to control) is starting to go bad after 16 years in operation.

The Output always maxes at 2 Volts ( 0 - 10 Volts).

Anyone have any suggestion on what I can do?